- Paper & Packaging Testing Instrument

- Textile Testing Instrument

- Plastic & Rubber Testing Instrument

- PU Foam Testing Instrument

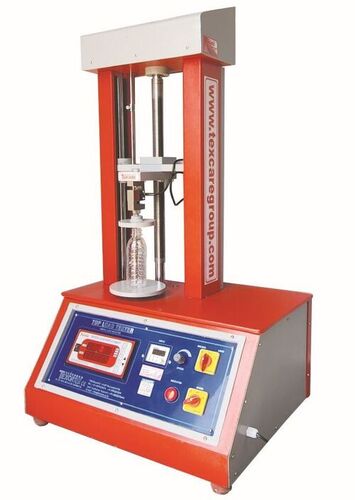

- Pet & Preform Testing Instrument

- Test Chamber /Hot Air Ovens

- Footwear Testing Instrument

- Tensile Testing Machine

- Tensile Strength Testing Instrument

- Industrial Ovens

- Muffle Furnace

- GSM Testing Instrument

- Fabric Testing Instruments

- Yarn Testing Instrument

- Hot Plate

- Conditioning Chamber

- Humidity Chamber and Incubator

- Universal Testing Machine

- Strength Testing Instruments

- Textile Dyeing Machinery

- Garment Testing Equipments

- GSM Cutter

- GSM Scale

- Dumbbell Cutting Press

- Gravity Balance

- Drape Meter

- Bursting Strength Testing Instrument

- Transparency Testing Instrument

- Elongation Testing Instrument

- Ageing Oven

- Extensometer

- Fatigue Testing Instrument

- Bundesmann Apparatus

- Colour Matching Cabinet

- Crock Meter

- Fastness Testing Instrument

- Swatch Cutter

- Abrasion Testing Instrument

- Pilling Testing Instrument

- Water Bath

- Gloss Meter

- Box Compression Testing Instrument

- Rotary Shaker

- Cable Connector Mating Cycle Tester

- Coefficient of Friction Tester

- Dart Impact Tester

- Bottle Perpendicularity Tester

- Base Clearance Membrane

- Martindale Abrasion Cum Pilling Tester 4 Head

- CBR Punchutre Strength Tester

- CBR Puncture Strength Tester

Showroom

Packaging is an imperative element of any material or product. However, to confirm its strength and compatibility, we have Paper and Packaging Testing Instruments that can test tensile strength, adaptability, foldability and many more factors. They have a platform on which the paper material is supposed to be placed for immediate and accurate results.

The provided Textile Testing Equipment is fabricated in adherence with industrial standards to provide accurate output rate within short period. It is useful for knitted, woven and different kinds of fabrics. This is primarily utilized to test the color-fastness properties of any fabric.

Texcare Instruments Limited provides Rubber and Plastic Testing Instruments for evaluating the properties of plastic resins, pipes, tapes and many more products. These are robust and compact, which make them highly functional under all operational conditions.

With foam, numerous companies make mattress, paddings and different products. And to test the strength and longevity factor of such material, they also use Foam Testing Instruments that are configured to carry out tensile and compression examination on mattresses and furniture.

Our Pet and Preform Testing Instruments are delineated to examine the effect resistance of different plastic materials such as PVC, PE and HDPE. They are additionally utilized to estimate the adhesion permanence of numerous pressure sensitive items.

These Hot Air Ovens are used to secure the packaging amid transportation period. They are immensely utilized in medical and textile industry. These have functional life frame, special structure and least handling alongside installation requirements. They can also endure higher pressures and temperatures for which the users require to configure the settings.

Our Footwear Testing Instruments will help the customers in making durable and strong footwear items. They are utilized to check the strength of fabric, rubber sole and laces. In addition, these can perform every relevant test, which is applicable in footwear development and design sector.

The provided Tensile Testing Machines are utilized to estimate the tensile strength of different items such as cement, steel, plastic and many more. They are outlined in a corrosion safe structure that ensures their longevity under differentiated working conditions.

To check the tensile and compression strength of steel and non-steel materials, our Tensile Strength Testers are the best instruments available in the market. They deliver accurate results and highly utilized for elongation, digital indication and electronic load measurements.

For effective temperature testing, curing, sterilization and allied procedures, our Industrial Ovens are ideal to perform these under any conditions. Inferable to their unmatched highlights, they are utilized in mining, research and production industries. These have chambers, which come with temperature homogeneity.

Typically, our Muffle Furnaces are a heat treatment boxes that are utilized to changeover the physical characteristics at elevated temperatures. They are beneficial for laboratories of rice, steel, and paint. The main functions of our furnaces include ash determination, lime calcination, normal laboratory checking and coal analysis.

Our GSM Testing Machines are applicable on different products such as paper and fabric. They have automated switch that enables the workers to make samples in compliance with given length and size. These also have a control panel, which is safe from humidity, elevated temperatures and chemicals.

Fabric is a simple material yet it comes tested for different properties before coming into the market. For such testing, we have Fabric Testing Instruments that aids in evaluating the length, fineness, strength and density of any clothing material such as polyester, leather, cotton and silk.

For determining the properties of a yarn, our Yarn Testing Equipment is immensely used to measure moisture regain, diameter, thread count and tension. This can be used both for education and commercial purposes. It is small in size, which consumes minimum space to deliver immense and precise results.

This Hot Plate range is a thermal, stable, and evaporative resistance measuring instrument, which is availed by numerous industries. The height can be adjusted as per the specimen for test it on different parameters.

When the companies procure materials from the vendors or the market, they generally test them of various grounds such as strength, performance and quality. For such operations, the customers can avail our Material Testing Instruments that complete their testing procedures in less to zero time.

The delivered Humidity Chambers and Incubators are pertinent tools for sterilizing and processing the materials for testing or final delivery. They have automated screen, soft key pads, and quality components that make them complete user-friendly. These are structured in tough metal material to resist humidity, pressures, chemicals and temperatures.

To check compressive and tensile strength of numerous materials, our Universal Testing Machines are immensely used by different industries. They are universal because these can carry out distinctive tests on variety of materials and structures. These are modular and adaptable to suit numerous customers requirements.

Strength is imperative for any material to last longer. Therefore, to estimate its value, our Strength Testing Instruments are utilized for fasteners, tubes, couplings, cables and allied materials. They are also applicable in estimating the pressure demanded to flip a cover, enclose a drawer and container.

Are you seeking for specialized and adaptable applications? Our Textile Dyeing Machinery covers numerous applications for finishing and coloring of different fibers in distinctive forms, such as knitted and woven. In addition, they are versatile for varied color beam diameters.

With our Garment Testing Equipment, different textile companies can estimate the characteristics of substances on different parameters. It aids the workers to determine defaults in items or machines to enhance the overall standard and quality. Nevertheless, distinctive models can be delivered with some customized features only on special orders.

GSM Cutter Manufacturer is provided by our

company, to our customers, to have better GSM cutter. This is tested under

various parameters to ensure its high quality and effectiveness. This is very

much liked and highly appreciated by our eminent customers, at nominal pricing,

in bulk quantities.

GSM Scales have wide application in rubber, textile, paper and also in other industries. These systems comprise of LCD display arrangement and standard working platform. Error free operation, easy operating system and long working life are their main features.

This range of Dumbbell Cutting Presses consumes 440 v voltage. These low noise machines have global design standard, high performance, have low operating cost and long working life. Offered machines are hydraulically powered.

This range of user friendly Gravity Balance systems has been designed as per global specifications. Light in weight, these apparatus are energy efficient. Accurate dimension, long lasting quality, compact shape and ease of handling are the key aspects of these products.

Stainless steel made Drape Meters are used to determine tensile strength of textile materials. These testing equipments are useful to detect deformation in fabric. High sensitivity and long working life are the key aspects of these machines.

Compact in appearance, this range of Bursting Strength Testing Machines is known for its computer controlled operation, compact shape and energy efficient mechanism. Production capacity of these apparatus varies as per their design and mechanism.

This array of Transparency Testers is used for PET bottles and sheets made of different grades of plastics. These testing systems have maximum 100% transparency range. These can maintain 2% accuracy while testing.

This range of digital Elongation Testing Machines is equipped with servo controlled based step motor and large display screen. Operation of these equipments is computer controlled. Long working life is one of their main aspects.

These high performance Ageing Ovens are utilized to detect any alteration in the mechanical properties of polymer and rubber at particular heat. These ovens are equipped with aluminum made inner cell.

This array of Extensometers is used for determining stretching and recovery properties of different fabrics. These mild steel made machines can be operated at maximum 100 degree C temperature. Long working life is one of their main aspects.

This array of Fatigue Testing Machines is used for textile material testing purpose. Made of stainless steel, these machines consist of 75 mm roller and working platform that has 6 mm length.

Stainless steel made Bundesmann Apparatus is used for testing water repelling capacity. These electric apparatus have 400 x 100 x 110 mm dimension. Designed by skilled technocrats, these apparatus have long working life.

Color Matching Cabinets are utilized to inspect colored products in paint making, automotive, paper and textile industries. Tube lights of these cabinets are separately controlled by electronic ballast for their quick starting and also to reduce their power consumption level.

Provided range of Crock Meters is known for its ergonomic look and accurate dimension. Controlled by AC power, these apparatus have ss spring clips and traverse counter. Long working life, user friendly mechanism and high strength are their main features.

This array of Fastness Testers is used to determine colorfastness of specific fabric post washing. These testers contain silicon gasket, digital timer and digital temperature controller. Copper immersion heater is used to raise their internal temperate.

This array of Swatch Cutters is required for precise cutting of leather, silicon, glass fiber and various other items. These cutting systems have different type of knives to suit exact production needs.

This array of Abrasion Testers is known for its error free mechanism and up to 3 kg load bearing capacity. Developed from mild steel or stainless steel, these abrasion testing systems have up to 85 kg gross weight. Design of these machines conforms to DIN norms.

This array of Pilling Testers is offered in various specifications. Maximum weight of these testers is 100 kg. Rotational speed of these testers is controlled by geared motor. Long working life and simple operating method are their main aspects.

This collection of Water Baths contain standard components like digital temperature indicator, controller etc. Entire structure of these systems is insulated with glass wool. Concave surface design and 90 degree operating temperature are their main aspects.

Box Compression Testers offered by us are reckoned for their energy efficient mechanism and microprocessor controlled functioning. Driven by single phase AC motor, these testing apparatus have 50 Hz frequency range.

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese