- Paper & Packaging Testing Instrument

- Textile Testing Instrument

- Plastic & Rubber Testing Instrument

- PU Foam Testing Instrument

- Pet & Preform Testing Instrument

- Test Chamber /Hot Air Ovens

- Footwear Testing Instrument

- Tensile Testing Machine

- Tensile Strength Testing Instrument

- Industrial Ovens

- Muffle Furnace

- GSM Testing Instrument

- Fabric Testing Instruments

- Yarn Testing Instrument

- Hot Plate

- Conditioning Chamber

- Humidity Chamber and Incubator

- Universal Testing Machine

- Strength Testing Instruments

- Textile Dyeing Machinery

- Garment Testing Equipments

- GSM Cutter

- GSM Scale

- Dumbbell Cutting Press

- Gravity Balance

- Drape Meter

- Bursting Strength Testing Instrument

- Transparency Testing Instrument

- Elongation Testing Instrument

- Ageing Oven

- Extensometer

- Fatigue Testing Instrument

- Bundesmann Apparatus

- Colour Matching Cabinet

- Crock Meter

- Fastness Testing Instrument

- Swatch Cutter

- Abrasion Testing Instrument

- Pilling Testing Instrument

- Water Bath

- Gloss Meter

- Box Compression Testing Instrument

- Rotary Shaker

- Cable Connector Mating Cycle Tester

- Coefficient of Friction Tester

- Dart Impact Tester

- Bottle Perpendicularity Tester

- Base Clearance Membrane

- Martindale Abrasion Cum Pilling Tester 4 Head

- CBR Punchutre Strength Tester

- CBR Puncture Strength Tester

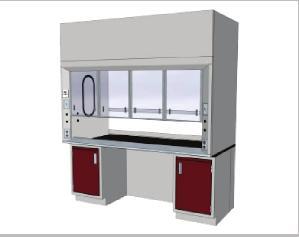

Fume Hood

65000 INR/Unit

Product Details:

- Accuracy 5%

- Shape Rectangular

- Speed Range Variable Air Velocity 0.3-0.5 m/s

- Control Type Touch Panel Controls

- Display Type Digital LCD Display

- Glass Type Tempered Safety Glass

- Features Automatic Sash Movement, LED Lighting, Low Noise Operation

- Click to View more

X

Fume Hood Price And Quantity

- 1 Unit

- 65000 INR/Unit

Fume Hood Product Specifications

- Single Phase 220 V, 50 Hz

- 1200 mm x 800 mm x 2300 mm

- Up to 180C

- 220 V AC

- Laboratory Fume Hood

- Chemical Laboratories, Research Institutes, Pharmaceutical QC/QA

- Automatic Sash Movement, LED Lighting, Low Noise Operation

- Powder Coated Mild Steel, Stainless Steel

- Fume Extraction

- Tempered Safety Glass

- Digital LCD Display

- Touch Panel Controls

- Variable Air Velocity 0.3-0.5 m/s

- Rectangular

- Mild Steel Body with Epoxy Powder Coating

- 5%

- 1.5 kW

- 400 L

Fume Hood Trade Information

- 20 Unit Per Day

- 4 Week

Product Description

Fume Hood

Utilization of this Fume Hood can be noticed in chemical laboratory, hospitals etc. Compact in shape, this product is fire proof and water protected. Made of PP and stainless steel, this product has standard accessories like gas fitting arrangement, socket, light, eyewash etc. Its design has been created by using advanced software. Offered Fume Hood is completely protected against corrosion, acid, high temperature, fire and scratch. The panel of this product has been developed by using finest grade leather grain to provide it an aesthetic look. Its standard has been checked as per its safety norms, features, design and dimension.

Efficient Filtration and Airflow Monitoring

The fume hood integrates activated carbon and HEPA filtration to effectively trap hazardous fumes and particulates. A digital airflow monitor continuously measures and displays airflow levels, ensuring safe operation and regulatory compliance. Precision airflow control maintains air velocities between 0.3-0.5 m/s, with an accuracy of 5%, reducing risk while optimizing user safety during chemical handling.

Robust Construction and Temperature Resistance

Manufactured with a mild steel body finished in epoxy powder coating, corrosion-resistant PP ducts, and a chemical-resistant ceramic work surface, this fume hood is designed for durability. It resists high temperatures up to 180C and harsh chemical environments typical in research applications, maintaining performance and structural integrity over extended periods.

Advanced Safety and Control Features

Equipped with an emergency power cut-off, alarm system, and touch panel controls, the fume hood ensures user safety in case of unexpected incidents. Automatic sash movement and gas, water, and vacuum service connections further enhance operational convenience. The digital LCD display allows easy monitoring and adjustment of key parameters, promoting a controlled and ergonomic workspace.

FAQs of Fume Hood:

Q: How does the built-in LED lighting enhance laboratory workflow within the fume hood?

A: The built-in LED lighting provides bright, energy-efficient illumination over the work area, improving visibility and accuracy during chemical handling and experiments. This reduces eye strain and increases safety during critical procedures.Q: What is the role of activated carbon and HEPA filters in this fume hood system?

A: Activated carbon and HEPA filters work together to capture and neutralize hazardous chemical vapors, fumes, and particulate matter, ensuring cleaner air both inside the hood and in the laboratory environment, thereby strengthening personnel protection.Q: When should the emergency power cut-off and alarm system be used?

A: The emergency power cut-off and alarm system should be activated immediately in case of electrical faults, chemical spills, or operational emergencies to swiftly halt all system functions and alert users, helping prevent accidents or exposure.Q: Where is the fume hood typically installed and utilized?

A: This laboratory fume hood is installed in chemical laboratories, research institutes, and pharmaceutical QC/QA departments where safe extraction and filtration of hazardous fumes are essential for maintaining a healthy workplace.Q: What benefits does the polycarbonate sliding sash provide compared to traditional glass sashes?

A: Polycarbonate sliding sashes offer superior impact resistance and are lighter than traditional glass, ensuring safer operation and smoother movement without compromising the clear visibility required for laboratory tasks.Q: How does the digital airflow monitor and control panel simplify fume hood operation?

A: The digital airflow monitor, together with touch panel controls and an LCD display, allows users to track, adjust, and maintain optimal airflow conditions with ease, contributing to safe and consistent best practices in chemical handling.Q: What process is recommended for cleaning and maintaining the ceramic work surface of the fume hood?

A: To clean the chemical-resistant ceramic work surface, use approved laboratory cleaners and avoid abrasive materials, ensuring spills are wiped promptly to preserve the surface integrity and maintain a safe, hygienic environment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese