- Paper & Packaging Testing Instrument

- Textile Testing Instrument

- Plastic & Rubber Testing Instrument

- PU Foam Testing Instrument

- Pet & Preform Testing Instrument

- Test Chamber /Hot Air Ovens

- Footwear Testing Instrument

- Tensile Testing Machine

- Tensile Strength Testing Instrument

- Industrial Ovens

- Muffle Furnace

- GSM Testing Instrument

- Fabric Testing Instruments

- Yarn Testing Instrument

- Hot Plate

- Conditioning Chamber

- Humidity Chamber and Incubator

- Universal Testing Machine

- Strength Testing Instruments

- Textile Dyeing Machinery

- Garment Testing Equipments

- GSM Cutter

- GSM Scale

- Dumbbell Cutting Press

- Gravity Balance

- Drape Meter

- Bursting Strength Testing Instrument

- Transparency Testing Instrument

- Elongation Testing Instrument

- Ageing Oven

- Extensometer

- Fatigue Testing Instrument

- Bundesmann Apparatus

- Colour Matching Cabinet

- Crock Meter

- Fastness Testing Instrument

- Swatch Cutter

- Abrasion Testing Instrument

- Pilling Testing Instrument

- Water Bath

- Gloss Meter

- Box Compression Testing Instrument

- Rotary Shaker

- Cable Connector Mating Cycle Tester

- Coefficient of Friction Tester

- Dart Impact Tester

- Bottle Perpendicularity Tester

- Base Clearance Membrane

- Martindale Abrasion Cum Pilling Tester 4 Head

- CBR Punchutre Strength Tester

- CBR Puncture Strength Tester

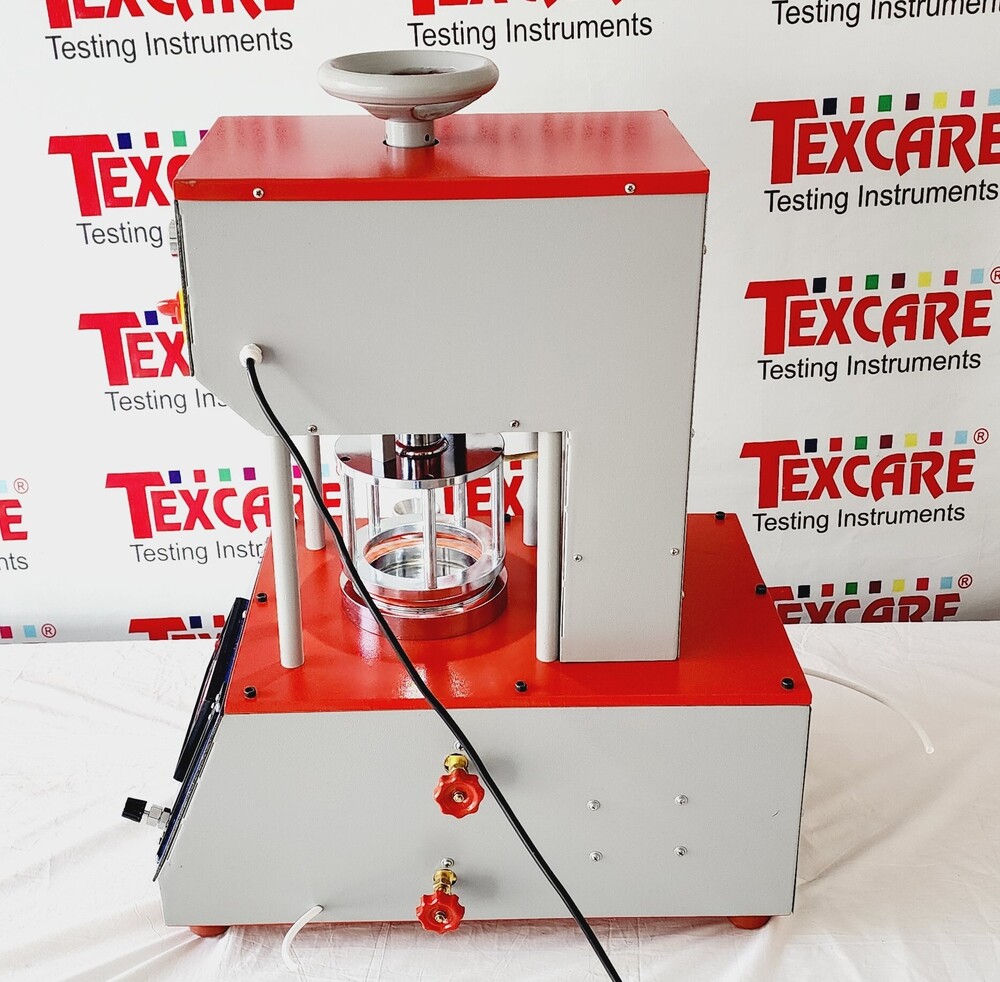

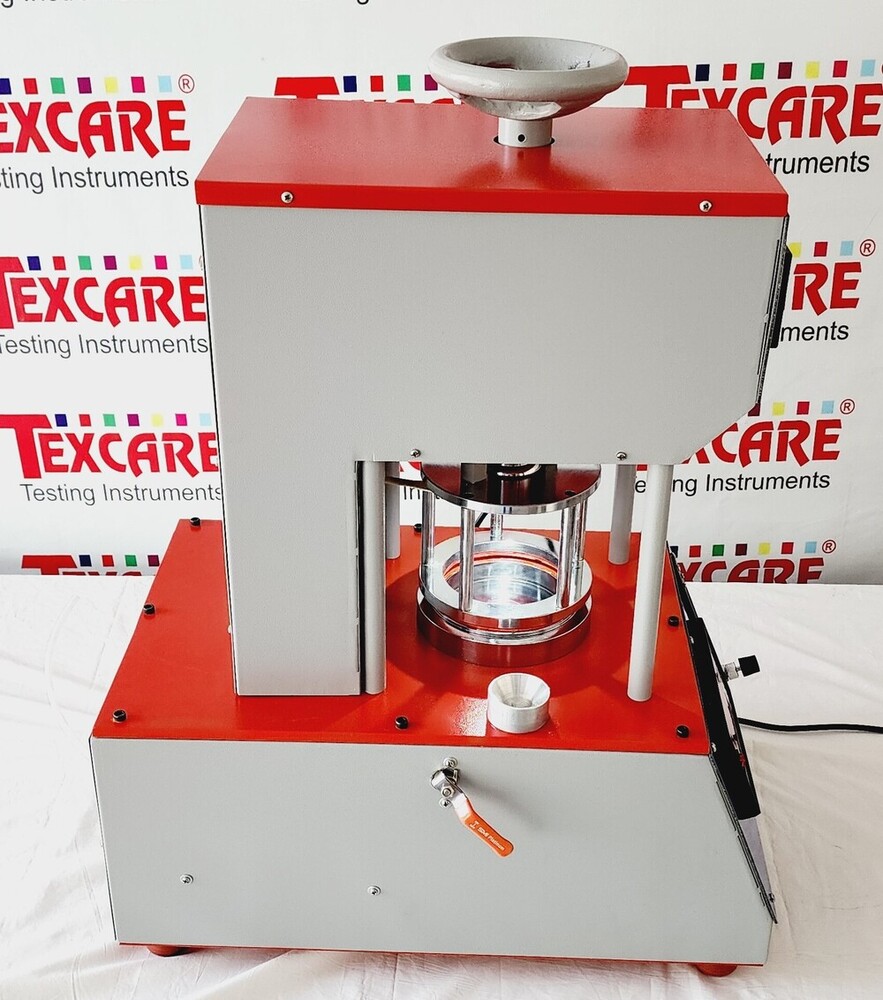

Hydro-Static Pressure Head Tester

80000.00 INR/Unit

Product Details:

- Test Range 0 - 5 kg/cm2

- Test Material Textiles, Non-wovens, Laminated Fabrics

- Number of Specimens 1 at a time

- Specimen Size Diameter 100 mm

- Port Size 6 mm

- Gas Pressure Up to 5 kg/cm2

- Humidity Up to 98% RH (adjustable)

- Click to View more

X

Hydro-Static Pressure Head Tester Price And Quantity

- 80000.00 INR/Unit

- 1 Unit

Hydro-Static Pressure Head Tester Product Specifications

- Electric

- 220V / 50Hz

- For Industrial Use

- 0 - 5 kg/cm2

- Textiles, Non-wovens, Laminated Fabrics

- 650 x 450 x 1200 mm

- 1 at a time

- Diameter 100 mm

- 6 mm

- Up to 5 kg/cm2

- Up to 98% RH (adjustable)

- Testing Hydro-Static Pressure Head of Fabrics

- Ambient (external control required for temperature conditions)

- Mild Steel

- Approximately 75 kg

Hydro-Static Pressure Head Tester Trade Information

- 20 Unit Per Week

- 4 Days

- Wooden Packing

- All India

Product Description

Hydro-Static Pressure Head Tester

This mild steel made Hydro-Static Pressure Head Tester is used for fabric testing purpose. Design of this testing apparatus conforms to global norms. Driven by AC power, this tester requires 220 V voltage and its frequency is 50 Hz. Rotational speed of its working table is 300 r/min. Offered Hydro-Static Pressure Head Tester is used for determining water penetration resistance properties of fabric. It adopts dynamic and static test methodologies. This tester has microcomputer controlled mechanism. The user can select three types of pressure range of this testing apparatus. This hydrostatic product consists of built in LED, highly sensitive pressure sensor and display screen.

Advanced Digital Pressure Measurement

Equipped with a digital pressure gauge, the system provides accurate, real-time monitoring of hydrostatic pressure, essential for consistent fabric testing. The RS-232 interface ensures reliable data export for documentation or analysis.

Reliable, Leak-Proof Testing Mechanism

The manual clamp creates a leak-proof seal around the specimen, preventing water ingress outside the test area. A transparent acrylic observation window allows users to closely watch fabric response during the test process.

Robust Industrial Design and Safety Features

Crafted from mild steel with a corrosion-resistant powder coating, this tester withstands harsh industrial environments. Safety is prioritized through automatic pressure cut-off and overload protection mechanisms, ensuring secure operation.

FAQs of Hydro-Static Pressure Head Tester:

Q: How is the Hydro-Static Pressure Head Tester used for fabric testing?

A: To test fabrics, place a specimen (100 mm diameter) in the clamp, create a leak-proof seal, set the desired testing parameters via the microprocessor controller, and start the test. The system will apply water pressure up to 5 kg/cm2, measuring water penetration in compliance with key industry standards.Q: What standards does this tester comply with?

A: The instrument is suitable for hydrostatic pressure head testing according to AATCC 127, ISO 811, and BS 3424 standards, ensuring international compatibility for textile and laminated fabric evaluation.Q: When should the test duration be programmed?

A: Test duration can be set from 0 to 99 minutes depending on the specific requirements of the testing protocol or material type. Program the timer before starting the measurement for precise and repeatable results.Q: Where is the Hydro-Static Pressure Head Tester primarily used?

A: This equipment is designed for industrial settings such as textile manufacturing, quality control laboratories, and research facilities, particularly suited for exporters, manufacturers, and suppliers in India.Q: What is the process for adjusting humidity during testing?

A: Humidity inside the test chamber can be adjusted up to 98% RH to simulate different environmental conditions. External control is required for temperature changes, providing flexibility when evaluating fabric performance.Q: What are the benefits of the microprocessor-based controller and RS-232 interface?

A: The microprocessor-based controller ensures precise regulation of test parameters and automatic safety features, while the RS-232 interface enables effortless data transfer for analysis and record-keeping.Q: Can non-woven and laminated fabrics also be tested using this equipment?

A: Yes, in addition to woven textiles, the tester is versatile enough for testing non-wovens and laminated fabrics, making it ideal for comprehensive material evaluation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese